[ad_1]

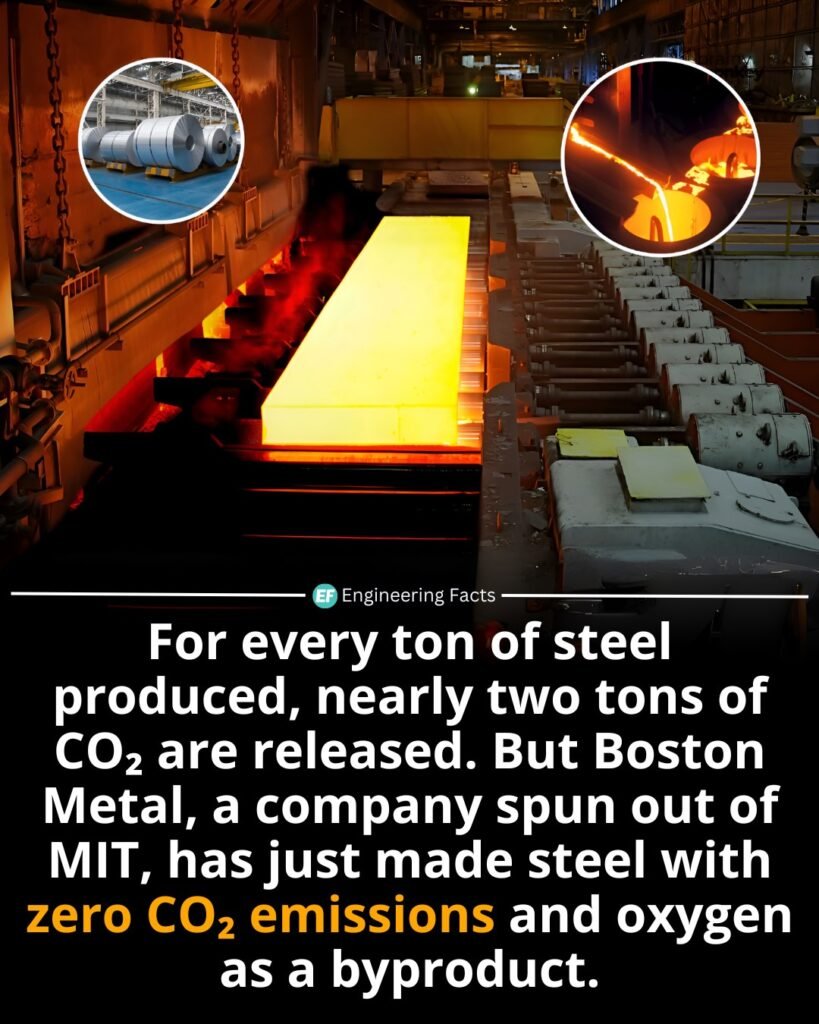

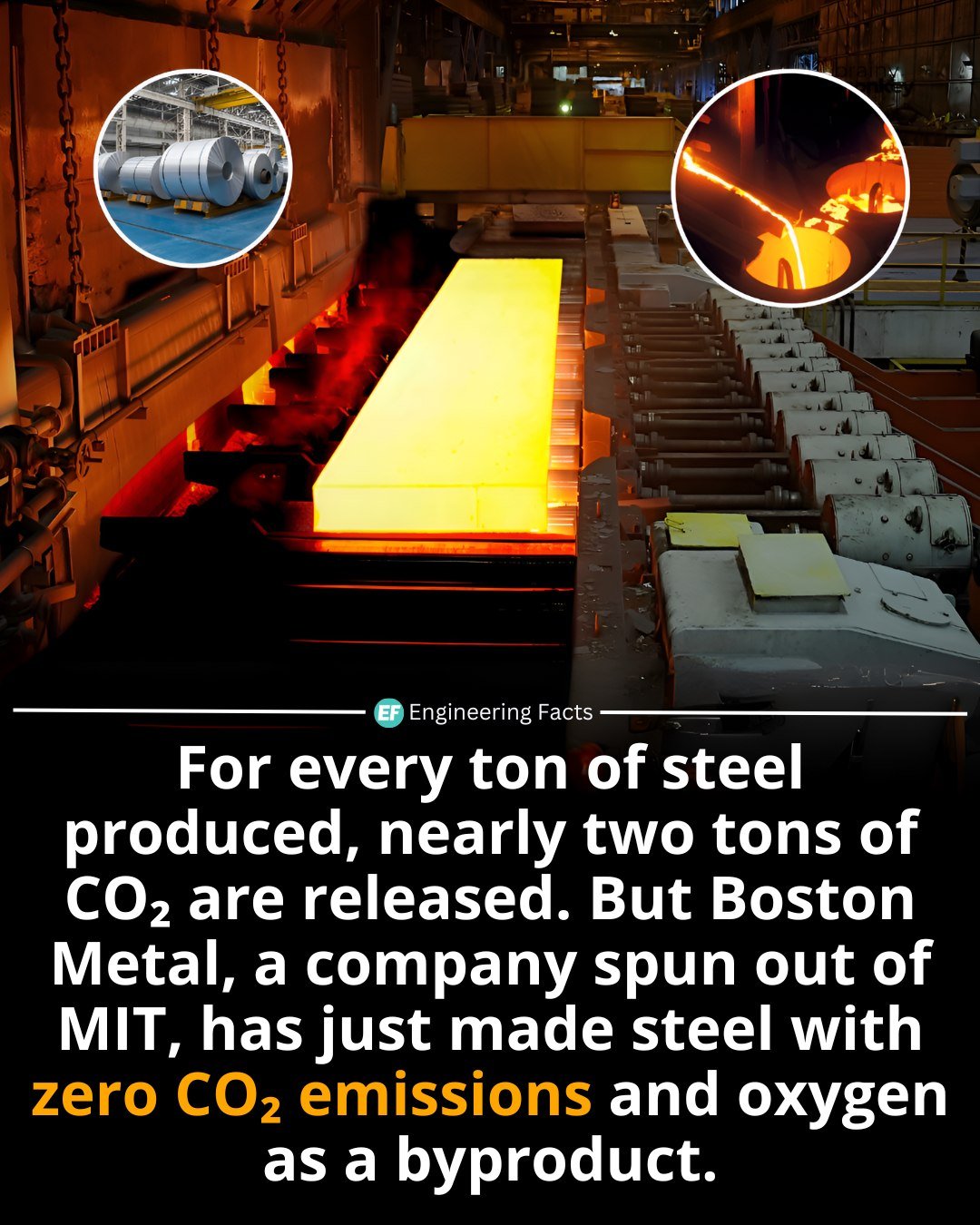

Steel production is one of the world’s dirtiest industrial processes—accounting for up to 9% of global CO₂ emissions. Traditionally, it relies on coal-fired blast furnaces to smelt iron from ore, producing nearly two tons of CO₂ for every ton of steel. But now, a revolutionary method by Boston Metal, an MIT spinout, might change that forever.

Using molten oxide electrolysis (MOE), Boston Metal skips the coal entirely. Their system heats iron ore with electricity to 1,600°C, splitting it into pure molten iron and oxygen. No carbon emissions—just clean, scalable steel. In March 2025, they successfully produced over a ton of this green steel, with plans for a commercial-scale plant by 2026. If powered by renewables, this method could help decarbonize an entire industry.

,GreenSteel ,BostonMetal ,MITInnovation ,CleanEnergy ,Decarbonization

Stay Connected with NewsRT:

For the latest headlines and urgent updates, visit our Breaking News section. If you want to stay informed about global affairs, our World News page brings you top stories from around the world.

For entertainment lovers, check out our Entertainment category to catch up on celebrity news, movies, and trending shows. Sports fans can follow live scores and in-depth match reports in our dedicated Sports section.

Stay on top of your health with expert insights and wellness tips on our Health page. For the latest financial updates, market trends, and stock analyses, visit our Stock Market section.

Don’t forget to explore our homepage for more top stories, exclusive reports, and real-time news updates curated for you.